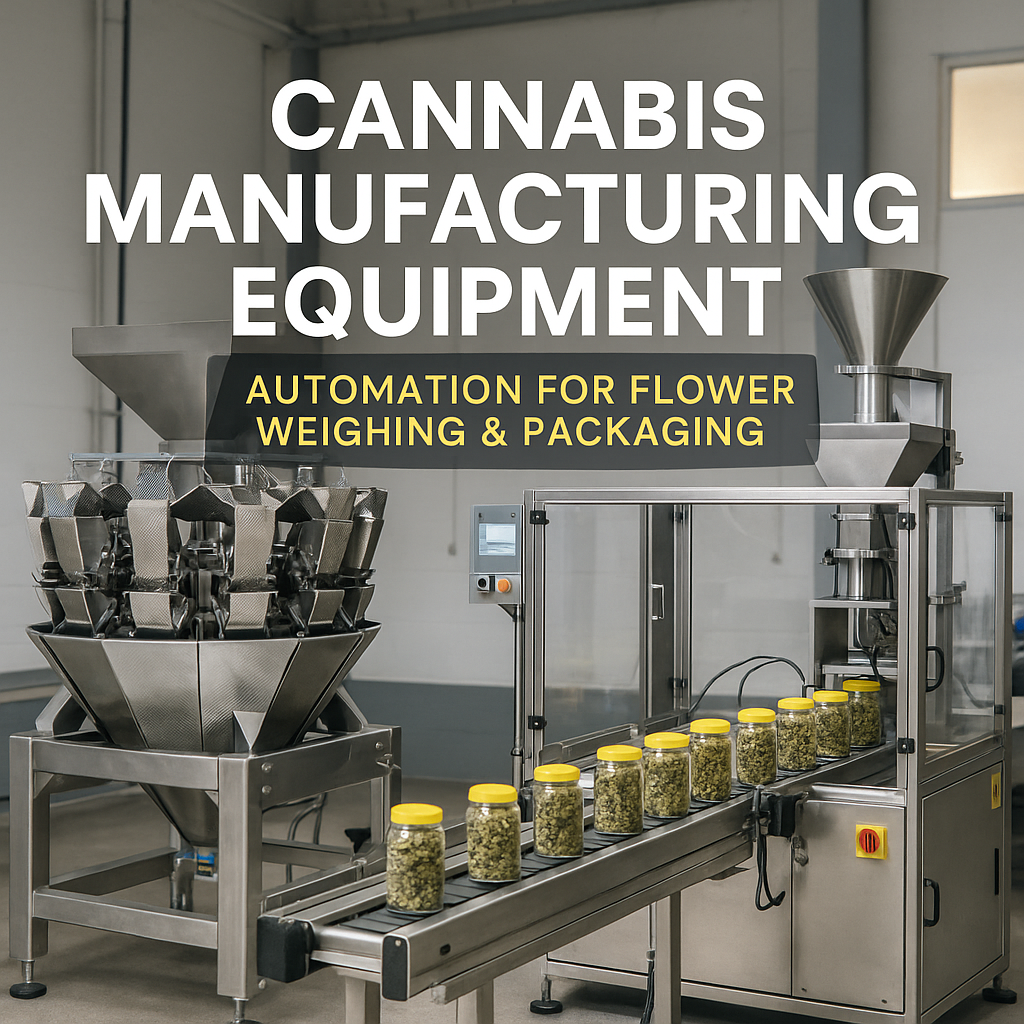

In today’s rapidly growing cannabis industry, manufacturers face constant pressure to increase efficiency while maintaining compliance. Every step of the supply chain is scrutinized, and even small mistakes can lead to costly losses. For businesses packaging dried flower, weighing is one of the most labor-intensive and error-prone processes.

This is where cannabis manufacturing equipment comes in. Automated weighing and packaging systems allow operators to reduce labor, improve product consistency, and protect margins. Instead of relying solely on manual weighing, companies can use specialized machinery to streamline production and ensure every package is accurate.

Why Automating Flower Weighing Matters

Cannabis is a high-value crop, and every fraction of a gram counts. Overpack by a few tenths of a gram across thousands of jars, and you’re giving away product that could have been sold. Underpack, and you risk compliance violations or customer dissatisfaction. Manual weighing not only slows down production but also introduces human error.

With the right cannabis manufacturing equipment, flower can be weighed, portioned, and packaged with consistent accuracy. Automated systems help operators:

- Reduce labor costs by minimizing repetitive tasks.

- Maintain compliance with precise, gram-level weighing.

- Increase throughput to meet growing demand.

- Improve product quality by reducing damage to flower.

- Generate audit-ready data for regulators.

Features to Look for in Flower Weighing Equipment

When evaluating cannabis manufacturing equipment for flower weighing, it’s important to focus on systems designed for precision and compliance. The most effective solutions typically include:

- Gram-Level Precision – Equipment should maintain tolerances of ±0.01–0.03 grams to avoid costly overpack.

- High Throughput Capacity – Multi-head weighers can fill hundreds or even thousands of units per hour.

- Gentle Handling Systems – Vibratory feeders or cushioned transfer systems protect trichomes and preserve flower quality.

- Integrated Checkweighing – Ensures each package is accurate before it leaves the line.

- Data Integration – Seamless connectivity with seed-to-sale systems to log weights, operators, and batch IDs. (Ok.. we wish. But it can at least help with prettier labels).

- Sanitary Design – Easy-to-clean stainless surfaces and modular construction support compliance and efficiency.

Cannabis Manufacturing Equipment Suppliers

Here are some leading companies offering automated weighing and packaging solutions for cannabis flower:

- Canapa Solutions – Manufacturer of the PrimoCombi® automatic cannabis weigh-filling machine, designed for jars, bags, and pouches.

- WeighPack / Paxiom – Offers complete packaging lines, including weigh-fillers, bagging, and labeling solutions.

- High Tek USA – Specializes in compact multi-head weighers built specifically for cannabis flower.

- Green Vault Systems – Provides precision batching and packaging systems with modular designs.

- LeafyPack – Focused on cannabis packaging automation, including weigh-filling systems.

- ActionPacUSA – Offers bud-weighing and packaging systems for consistent jar filling.

- Spee-Dee Packaging – Delivers jar-filling and checkweighing equipment with high accuracy.

- Yamato Americas – Supplies multi-head combination scales configured for cannabis weighing.

Implementation Best Practices

Investing in cannabis manufacturing equipment is not just about buying a machine — it’s about integrating automation into your workflow. Here are a few best practices to maximize results:

- Pilot Test with Actual Product – Bud size, moisture content, and density can affect performance. Always test with real flower before committing.

- Optimize Feed Systems – Hoppers, conveyors, and vibratory trays should be designed to move flower gently and consistently.

- Plan for Scalability – Modular systems allow operators to expand capacity without replacing entire lines.

- Prioritize Compliance Data – Choose equipment that logs batch details automatically for audit readiness.

- Train Operators – Even the most advanced equipment requires skilled staff to set up, maintain, and troubleshoot.

The ROI of Cannabis Manufacturing Equipment

The investment in automated flower weighing pays off quickly. By reducing overpack, companies protect profit margins. By avoiding compliance mistakes, they minimize regulatory risk. By scaling throughput, they meet demand more effectively without expanding labor costs.

In short, cannabis manufacturing equipment helps businesses move from manual, error-prone processes to streamlined, data-driven production. As the industry matures, operators that embrace automation will be positioned to compete on efficiency, compliance, and quality.

Conclusion

Automating flower weighing is one of the smartest upgrades a cannabis manufacturer can make. With purpose-built cannabis manufacturing equipment, businesses can increase speed, ensure compliance, and maintain product integrity. Suppliers like Canapa Solutions, WeighPack, High Tek USA, Green Vault, and others provide solutions that make automation accessible at different scales of production.

For operators, the message is clear: automation doesn’t replace people — it replaces inefficiency. In cannabis manufacturing, few investments deliver a faster or more reliable return than precision weighing equipment.

While investing in cannabis manufacturing equipment can transform efficiency, the technology is only as strong as the processes and people behind it. That’s why standard operating procedures (SOPs) and employee training are critical. Custom SOPs ensure your team uses equipment correctly, maintains compliance, and follows consistent workflows across shifts. Paired with online training programs, employees gain the confidence to operate machinery, troubleshoot issues, and prepare for inspections. Together, automation plus SOP-driven training creates a system that scales smoothly and reduces operational risk.